For IoT-driven machine and plant engineering, NORD DRIVESYSTEMS now offers solutions for making drive data available in real time in a cloud environment. All drive axes can be monitored from anywhere in the world via an Internet connection.

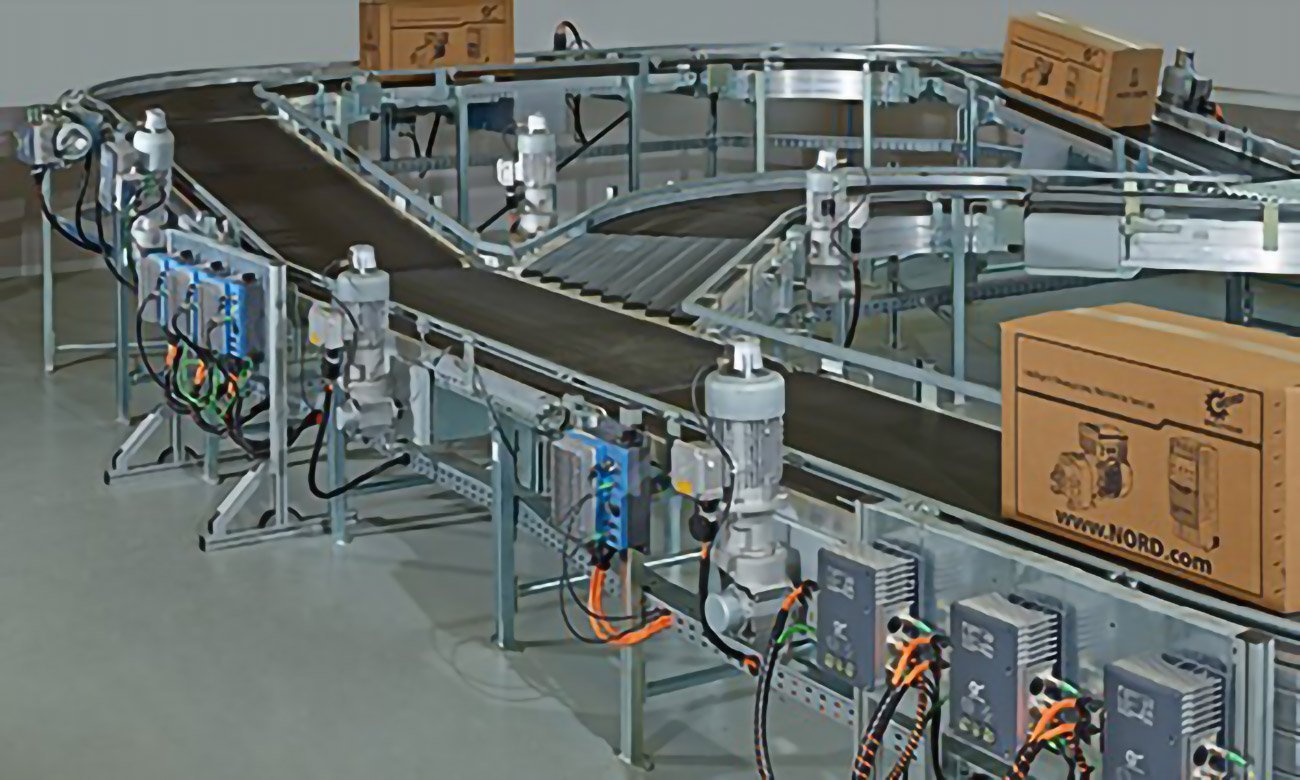

The concept was first deployed in the application test center at the German NORD headquarters, where it has been thoroughly tested and has proven its reliability in a drive network utilizing standard interfaces and components. AC vector drives and motor starters controlled via Profinet simultaneously transmit live status data in UDP packets, on the same bus line, without affecting regular control communication.

The cloud-enabled drives send data about their power consumption, speed, and voltage, as well as the status word. Tunneled through a Siemens PLC, all of this information is transmitted to an IoT gateway and on into the cloud. Status data can then be analyzed for energy profiling, asset management, and remote maintenance purposes. Of course, any overload and error states can be visualized. The drives can also transmit additional application data into the cloud at any time – for instance, data of connected sensors and actuators. Moreover, other parameters can be derived from available status data, notably current oil temperatures. NORD has successfully validated this in initial tests. Such data allows for conclusions about lubricant aging that can be used for predictive maintenance. NORD continues to work on and further refine IoT-related and Smart Factory concepts. Novel NORD drive solutions that have already been available for some time include economic condition monitoring implementations based on virtual sensors.

Source: Nord Drivesystems