In 2024, Open IIoT, a cohort of some of Australia’s best known automation companies, took their innovation to a new level with the unveiling of four new cutting-edge demo units.

The decision to develop multiple demo units marks an exciting departure for the group, who had previously combined all of the member companies’ technologies into one single automated system.

While the previous demo unit was able to demonstrate the seamless integration and interoperability of IIoT concepts in one physical system, their decision to showcase the power of automation through various Industry 4.0 applications opens up the group to a number of new possibilities.

“With the new approach we have combined the power of today’s network infrastructure and cloud connectivity to operate individual processes in remote locations,” explains Jozef Ceh, SMC’s Group Manager ANZ for Integrated Solutions and Open IIoT member. “This gives users enhanced access to our demo units, right down to the sensor level.”

As to the motivation behind Open IIoT’s new exhibition direction, Jozef shares that “the separate demo units demonstrate a more de-centralised approach to automation through the utilisation of high-speed broadband connections and sophisticated network protocols. These create connectivity between individual processes, that, while operating individually in separate physical locations, are accessible and controlled through a central user interface and deployed via the cloud.”

All four of Open IIoT’s new demo units are connected by ARGUS’ advanced SYMBIONT Cloud Deployment Software, an industrial automation and data management platform tailored for medium to large-scale enterprises in the manufacturing industry and other related sectors invested in digital transformation.

With its intuitive design that offers a low barrier to entry and straightforward interfaces, Symbiont places advanced system configuration and data contextualisation directly into the hands of end-users, bypassing the need for expensive integration services. The platform ensures rapid deployment in under five minutes through a Virtual Appliance that significantly simplifies complex data processes.

This approach is transformative, reducing implementation costs and enhancing flexibility, making it a powerful ally in the digital transformation journey.

A closer look at some of Open IIoT’s new demo units

SMC ANZ

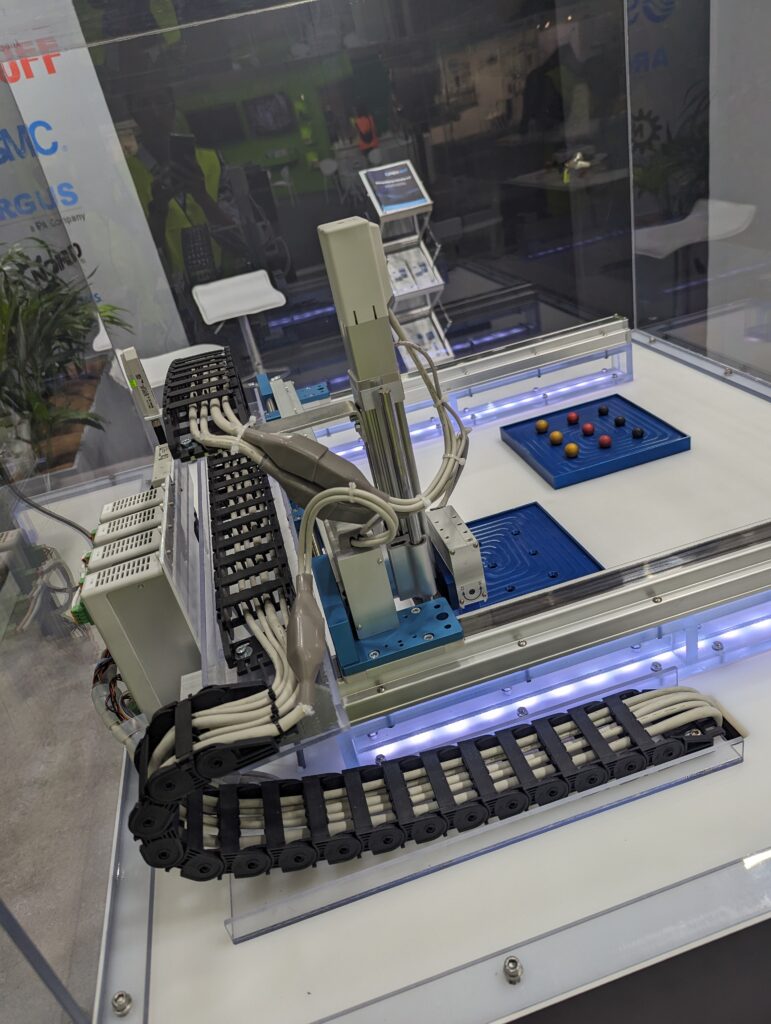

SMC capitalised on the recent release of their new EXW1 compact wireless system when developing their demo unit. While deceptively simple on the surface as a standard ‘pick and place’ application with an electric servo gantry system, the advanced technology used highlights SMC’s digital automation architecture. It features fellow member company Beckhoff’s EtherCAT connection to underpin the power of networking when it comes to remote control and data accessibility.

Further technical specs include a EXW1 IO-Link master wireless remote unit that integrates the benefits of IO-link into a wireless network while simultaneously offering game-changing versatility in the form of both Class A and B port specification. Finally, the unit integrates a JXC servo direct-input motor controller with safe torque-off feature, which promotes improved flexibility and security while ensuring accurate speed, position and force.

Balluff Australia

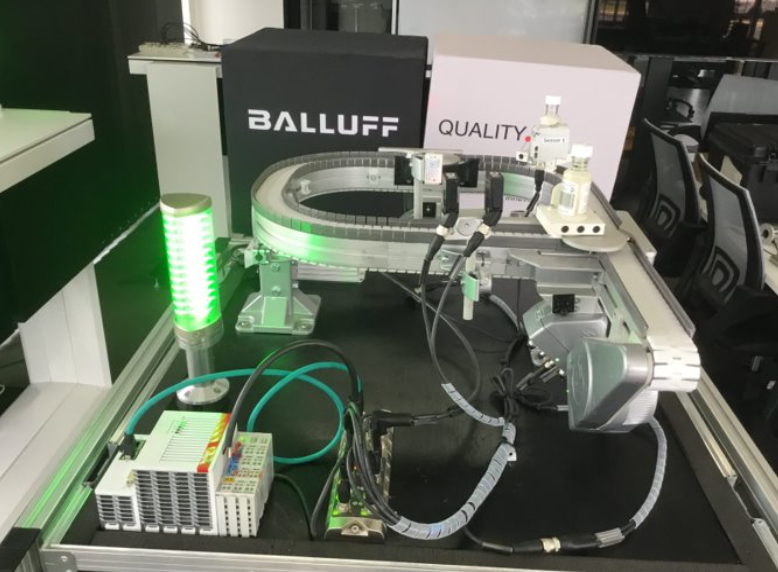

Focusing on improved measuring for improved performance, Balluff’s demo unit features IO-link devices and IIoT-enabled sensors to showcase how real-time production data can be gathered and interpreted more accurately. The company achieves this via an open standard network interface block, with collates data from several diverse sensor types and uses an industrial network to connect to a central controller. From here, data is transported from sensors to the cloud, where key indicators like position and temperature data can be visualised by users in real-time.

Balluff’s new demo unit highlights the link between sensors and more accurate condition monitoring, which assists with cutting-down on production downtime and ensuring consistency and quality. Crucially, condition monitoring also improves maintenance processes, by anticipating potential breakdowns and alerting users to possible issues before they become critical.

Beckhoff Automation

Taking a slightly different approach, Open IIoT member Beckhoff Automation’s demo unit will showcase their XPlanar Transportation System, which features a series of magnetic tiles that have unrestricted movement around the production area and can be used to hold products.

While the visual aspect of having unattached magnetic tiles floating around in space can be unnerving at first, XPlanar demonstrates maximum flexibility. The system overcomes the limitation of traditional assembly lines, that is, the requirement for objects to move through the production process in a strictly linear fashion. It is a strictly contactless system that offers high level of hygiene as dirt and debris cannot accumulate. Like the other demo units, XPlanar generates production data that is transported to the cloud using a controller, where data repositories can be analysed by SYMBIONT.

Join the Open IIoT Experts in ushering in a new era

Open IIoT is entering a whole new era of cutting-edge technology with the launch of their new demo units, and these advancements aren’t just limited to their technology. The group is actively looking for new member companies, in the fields of automation and IIoT, to expand their industry expertise. If you want to know more about becoming a member with the Open IIoT group, please Contact Us.

The world of Industry 4.0 is constantly evolving and with new technologies and applications being developed every day, Open IIoT recognises the need for fresh ideas and perspectives to enhance their role as Australia’s jargon-cutting IIoT experts.